New way to make cheap Graphene

New way to make cheap Graphene by GRAFOL researchers

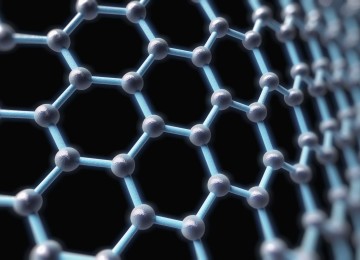

Researchers involved in the €10.6 million European research project called GRAFOL have reportedly demonstrated a cheap way to make roll-to-roll production tool capable of making large sheets of graphene on an industrial scale. The tool operates at atmospheric pressure and at reduced operating temperature, and is proclaimed by the researchers “the best route to low-cost manufacture”.

According to the GRAFOL project co-ordinator John Robertson, from the University of Cambridge, the key result of the four-year effort is the development of a roll-to-roll production tool capable of making large sheets of the single-layer carbon material.

In a post on the European Commission’s Horizon 2020 website, he said: “This is the first time something like this has been realized commercially; other developments in this field have mainly appeared in scientific journals. We have shown that the tool, which operates at atmospheric pressure and at reduced operating temperature, is the best route to low-cost manufacture.”

Some challenges remain, however, before graphene can become part of a commercial large-scale device manufacturing process since applying graphene to various other substrates still requires a problematic transfer process and a large-scale commercial demonstration of this step is required.

Among the commercial partners involved in the Seventh Framework Programme (FP7) effort were big-hitters Intel, Philips, and Thales, while GRAFOL also aimed to develop graphene-based optical modulators and integrate these within a silicon photonics platform.

Another application to benefit could be photovoltaics, with the potential for producing flexible thin-film solar cells with transparent electrodes.

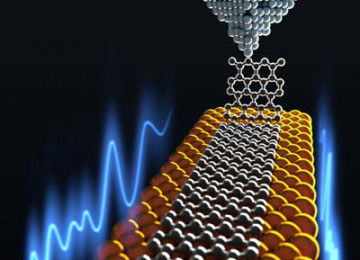

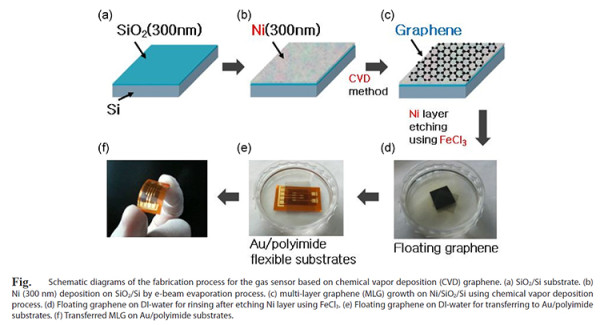

Image appear how vacuum of CVD works

Robertson summed up: “The project results will definitely attract companies from different sectors to graphene technology because the production costs are now at an affordable level for their industries.

Central to the project is the Germany-based company Aixtron, which is best known as a key supplier of metal-organic chemical vapor deposition (MOCVD) tools that are widely used to deposit active semiconductor layers in LED and laser diode structures.

As well as its realization of a roll-to-roll tool, the team showed that it is possible to adapt the chemical vapor deposition method to grow graphene on 300 mm-diameter silicon wafers – the standard size currently used in the semiconductor industry. That suggests the potential to integrate graphene in silicon photonics platforms.

The companies involved in the project also plan to take the project results to the next level by introducing new products in the market, like for example the roll-to-roll deposition tool, and all-carbon interconnects.”

Aside from Aixtron, the likely beneficiaries will include the Spanish company Graphenea. Founded in 2010, the San Sebastian firm sells graphene products in a variety of forms and is part of the European Commission’s ten-year Graphene Flagship research effort.